Internal Bar Heaters for 1 1/8 Handlebars

I have tried a number of bar heaters, heated grips and heated gloves but ceramic internal bar heaters have proven to be my favourite. They are very easy to install, allow me to run my preferred grips, do not increase the outside diameter of the grip, are quick and easy to use and have two heat settings with the highest setting being hot enough to ride in extremely cold, snowy conditions. I use the Polly Heater brand and while the company does not wholesale to motorbike companies, they are available on eBay by searching for "Polly Heater".

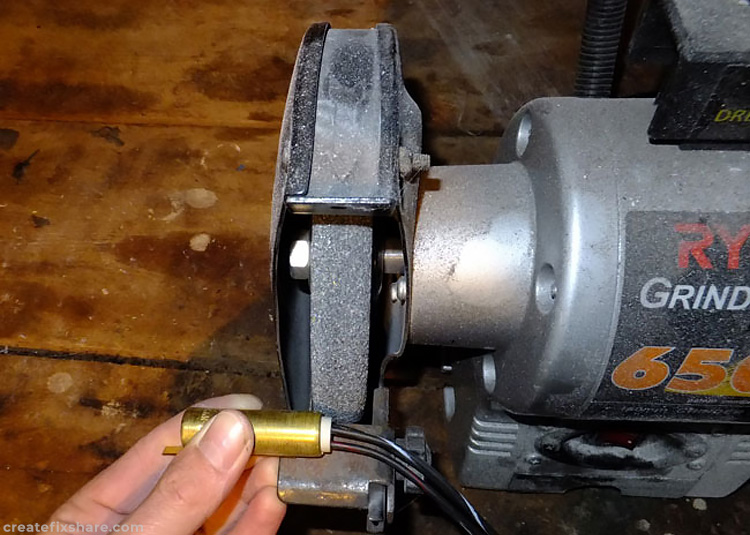

While building up a DRZ400 adventure bike and fitting it with 1 1/8" Renthal Fat Bars I hit a problem when going to install another set of Polly Heaters, the problem was they wouldn’t fit. The reason being is that 1 1/8" bars have an internal diameter of 14 mm opposed to the 7/8" bars having an internal diameter of 17 mm. Trying to find a ceramic bar heater to fit the smaller internal diameter of 14mm came to a dead end, after hours of searching the web and phoning multiple bike shops, I found no solution.

For a while I resorted to using Oxford Heated Grips. While these are a good product, they increase the OD of the grips and I don't like that. I had the idea to strip down the ceramic bar heaters to see if they could be modified to fit and the result couldn’t have been any better.

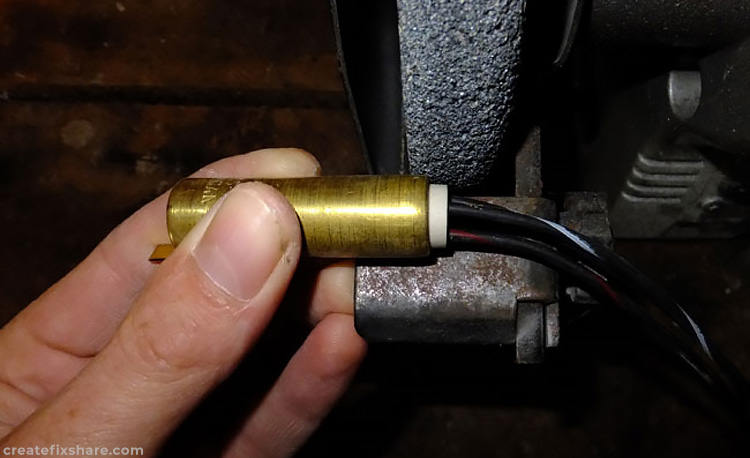

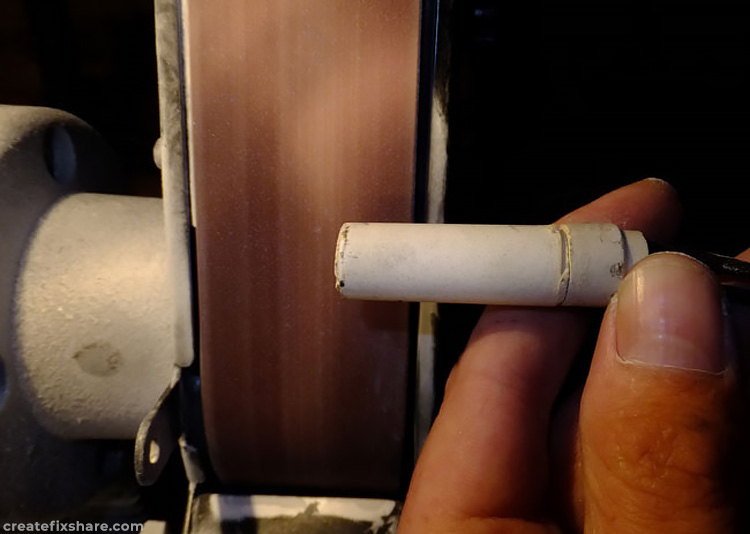

By stripping the metal casing from the Polly Heaters it leaves you with the bare ceramic heater that is a perfect fit inside 1 1/8" bars. By removing the metal case you are left with the ceramic heater. This is a delicate piece of ceramic however if you are careful while preparing them for the install, they slip inside the bars with an almost perfect fit and regain protection by being housed inside the bar itself.

Below is a photo step by step of the process I used to take a set of Polly Heaters, strip the casings and install them into a set of Renthal 1 1/8" Fat Bars.