DRZ400 Engine Rebuild

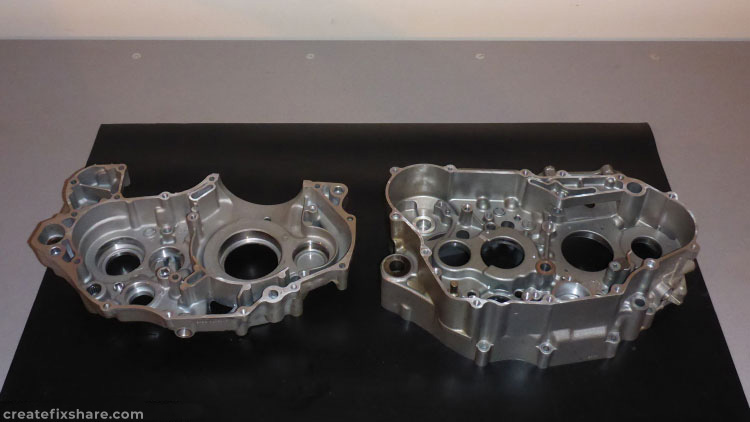

This article follows the process of a DRZ400 engine being rebuilt after running a bottom end bearing. It starts at the very beginning with cases apart. Because of running a bearing and potential metal contamination throughout the entire engine, the goal is to remove and replace all crankcase bearings. Following that it will be a process of dissemble, clean, inspect and measure every part subject to wear or that could potentially be harbouring contaminants.

This isn’t a comprehensive rebuild article with exact assembly sequences, torque specs etc, however it shows the majority of the steps and provides anyone interested in rebuilding a DRZ400 an excellent insight to the process.

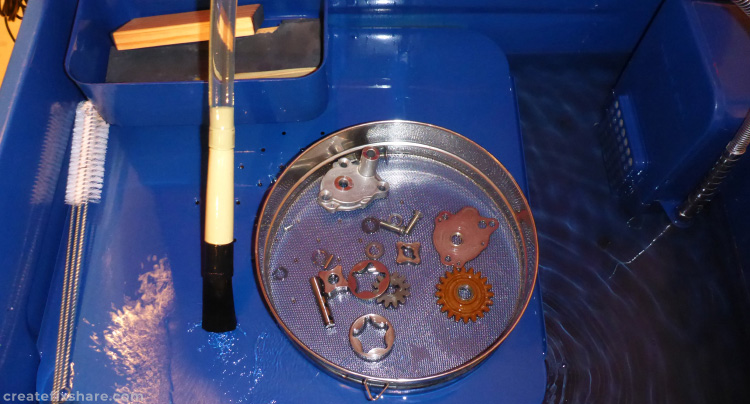

Oil Pump

After cleaning up the cases the transmission was next but I was waiting for new input and output shaft circlips so it was onto the oil pump. This was disassembled, washed, inspected for wear and then reassembled.

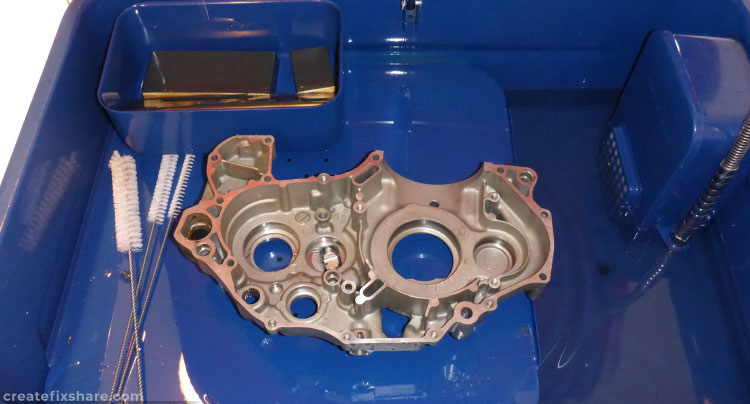

Transmission

With a parts delivery from Mr Suzuki which included the transmission shafts' circlips it was into the wash bath, clean, inspect, measure and reassemble.

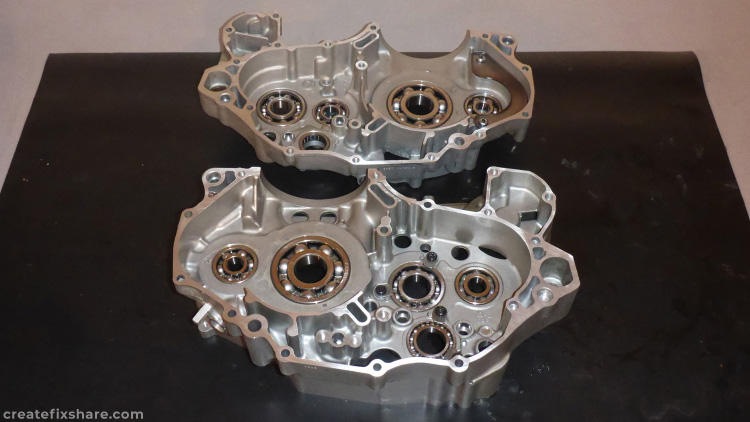

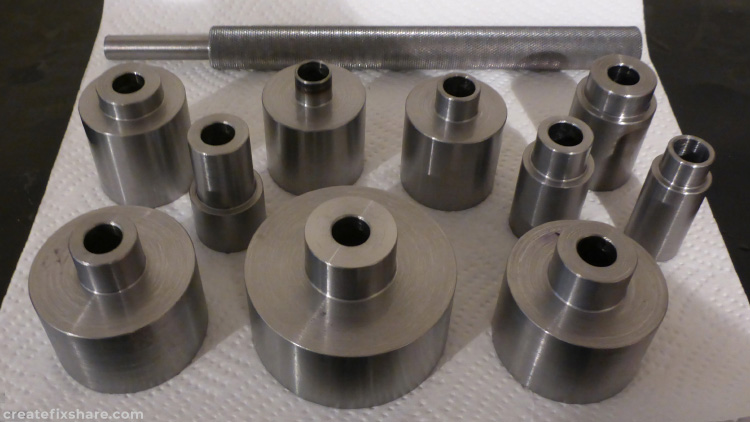

New Engine Bearings

With a package arriving with the set of engine bearings, it was onto installing them. The cases were heated to 80 degrees C and the bearings cooling to 5 degrees C so the combination of respective expansion/contraction provided minimal interference and easy installation.

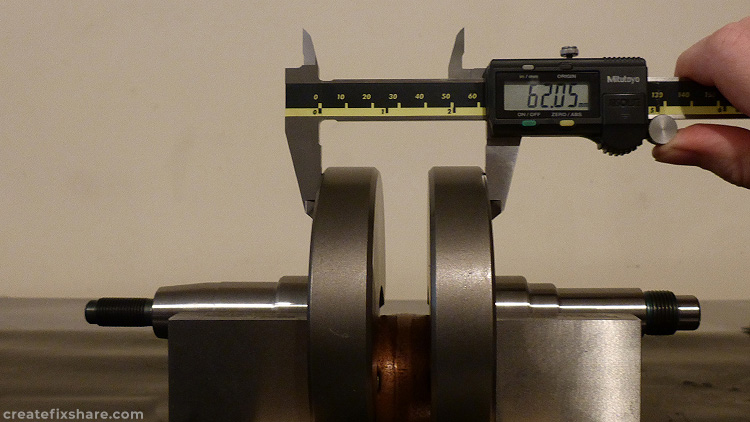

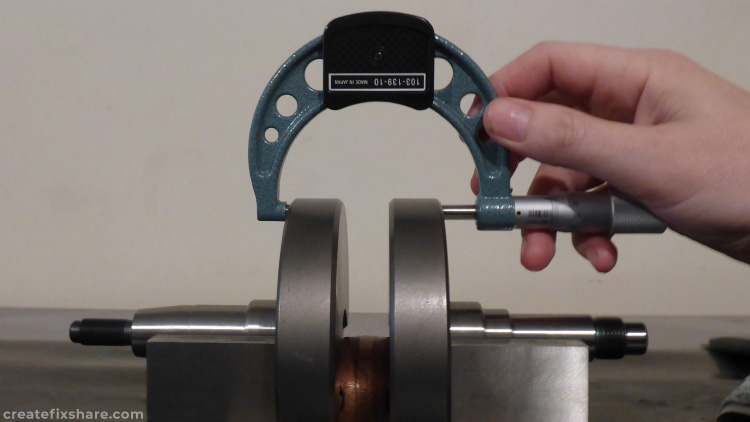

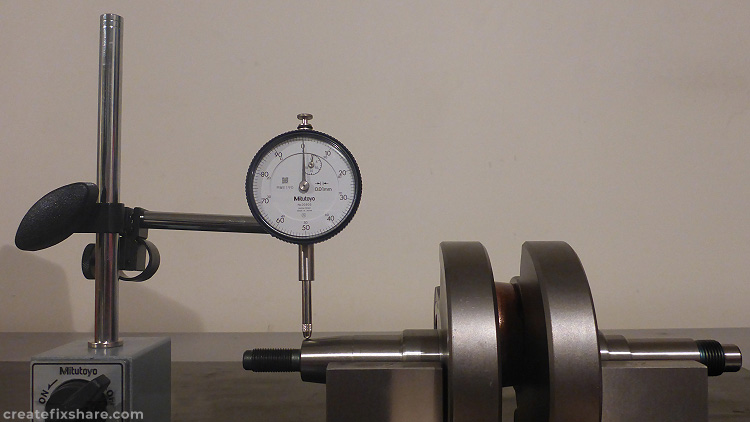

DRZ400 Crankshaft

With the complete set of engine bearings in, next up was the crankshaft. The first task was to throw the crankshaft in some V blocks and check if the web to web measurements were within spec. This is really a test of, did any of the freighting companies drop it before it reached my doorstep! Following that it was the DTI test to check crank run-out.